Finite Element Simulations of the Dynamic Behavior of Polymer-Bonded Explosives

- Polymer bonded explosives (PBX) refers to a class of composites consisting of crystals of explosives bound together by polymer binders and a small percentage of additives such as plasticizers and antioxidants;

- The mass fraction of crystals may vary over a range of 60% to 95%;

- Young’s modulus of elasticity of the crystal is typically an order of magnitude higher than that of the binder. As a result, the deformation characteristic of the composite is primarily influenced by the mechanical properties of the binder itself. Upon application of load, the binder deforms and absorbs most of the energy of deformation;

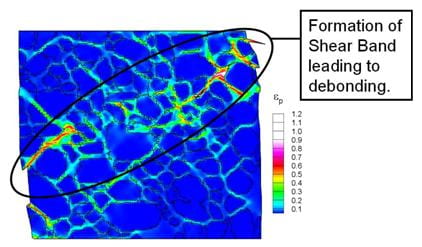

- Heating resulting from plastic deformation of the binder generates local hot spots and serves as an ignition mechanism;

- The model analyzed here consists of crystals of HMX evenly dispersed in a matrix of polymer HTPB. HMX granules are essentially elastic under the conditions analyzed although our model is capable of capturing any plastic deformation as well. A range of loading rate, initial temperature and volume fraction is considered to quantify the variation of deformation, stress and temperature in the microstructure;

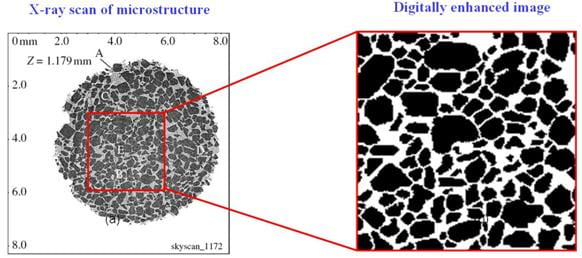

- Microstructure image acquired from X-ray microtomographic scan of simulant QRX030 by C.R. Siviour et al., Proc. R. Soc. A (2008);

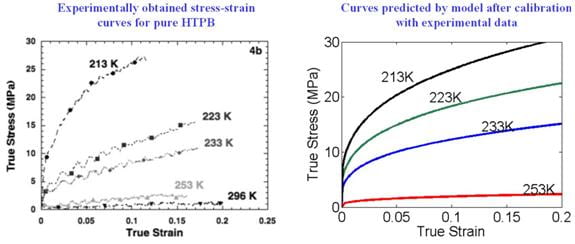

- Experimentally measured curves form C.M. Cady et al., Polymer Engineering and Science, 2006 are used to calibrate thermo-viscoplastic parameters;

- Shear banding is observed for microstructure having grain fraction: 0.64;

Ongoing and Upcoming Work

- More realistic characterization of constituent behaviors;

- Modeling of actual experimental configuration;

- Integration of cohesive fracture capability;

- Material synthesis;

- Experimental verification.